Computer tomography (CT)

Computer tomography (CT) is a testing technique that allows for three-dimensional reconstruction. This technique provides advanced analysis of error shape, position, and distribution. Depending on the application, slower, high-precision scans or faster scans can be used.

VJ technology provides you with the highest level of technical expertise in computer tomography (CT) available today. We can provide you with the best, ASTM approved, customized systems to meet your 100% requirements for this challenging application, including high-energy CT and microfocal CT. VJT can complete projects that other suppliers are unable or unwilling to accept. VJT also provides a "value CT" solution in our C-Arm system approach, combining high quality and affordable pricing into ordinary applications.

VJT can provide some CT techniques:

Standard cone beam CT

● Spiral CT

● Sliced CT

● Ultra long distance

● Translation and rotation

VJ Technologies provides you with the highest level of technical expertise in computed tomography (CT) today. We can bring the best, ASTM certified custom systems to your organization to 100% meet your requirements, which are challenging applications including high-energy CT and microfocal CT. VJT can complete projects that other providers cannot or are unwilling to accept. VJT's C-Arm series products include a "Value CT" that provides high-quality and cost-effective solutions for your daily applications.

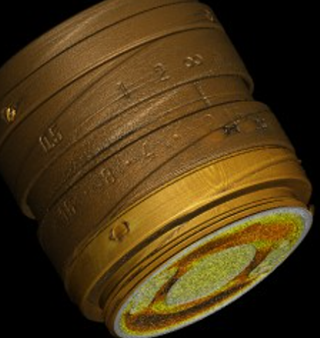

Casting scan displaying pores

Visualized 3D volume

VJ Technologies CT allows you to view and analyze the three-dimensional structure of the inspected object. The VJT CT method combines our advanced VJT image acquisition/capture capabilities with the Vi3 image processing software suite.

In typical 3D applications, it is necessary to record multiple views to obtain 3D images. This method is both costly and time-consuming. VJT provides a hybrid solution that layers CT functionality as necessary on the same platform and system to achieve most functions. This seamless approach saves time and money, and is a powerful part of our Vi3 software suite.

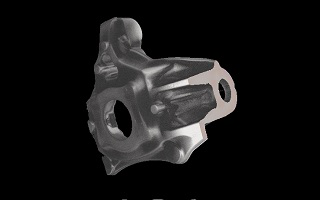

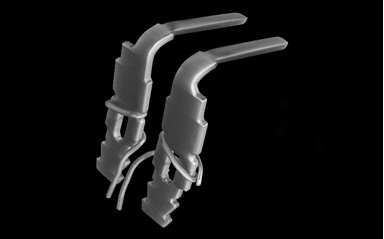

CT reconstruction of automotive joints Three dimensional isometric view of electronic components

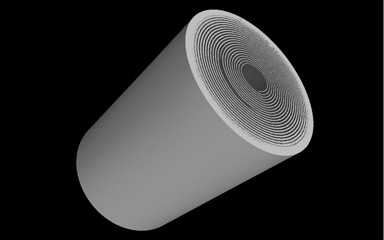

A three-dimensional isometric view of a coil

Leading concept

VJT collaborates with the Fraunhofer Research Institute in Germany to create and integrate software and technology for projects including the European Space Agency

VJT collaborated with Lawrence Livermore National Laboratory to elevate CT technology to a new level and address some of the biggest challenges facing NDT today.

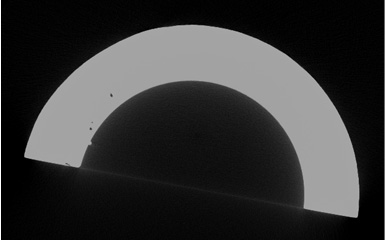

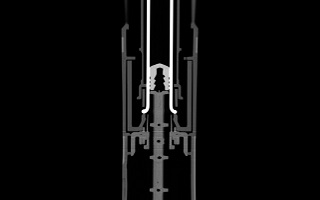

CT image slicing of a medical device

case study

The British Society for Non destructive Testing has published an article on VJT CT capabilities. It describes how VJT enables US military personnel to 100% inspect an ammunition production process, with inspection times for each item being less than 60 seconds.

VJT has been entrusted with the responsibility of inspecting the rear skirt of the recovered NASA space shuttle booster rocket. Due to the large conical structure installed on the rocket being too large for inspection, VJT has developed a patented fault synthesis solution to inspect components. This innovative CT technology allows for inspection of parts while 3D reconstruction of images is performed layer by layer to identify defects in the structure.