VJ Electronics provides SMT repair systems, X-ray inspection systems, and X-ray based point machines to leading companies worldwide. The application scope covers from bulk consumer products such as mobile phones, tablets, and gaming systems to medical devices, computers, networks, communications, automotive, and aerospace fields.

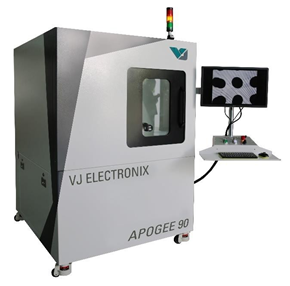

This is a micro-focused X-ray inspection equipment, mainly used for the inspection of BGA/CSP, inserted components, SOP/QFP, transistors, CHIP components, bottom electrode components, QFN, power modules, and the inspection of missing solder joints, non-wetting, solder quantity, offset, foreign matter, bridging, the presence or absence of pins, etc. (different options are made according to the inspection object). The inspection software independently developed by VJ can perform image processing, analysis, and automatic defect calculation on various electronic components.

XQUIK III-L is based on the principle of X-ray penetration imaging to obtain image information for non-destructive testing of various product items used in SMT production.

Equipped with a perfect combination of artificial intelligence deep learning software and cloud update system, using software algorithms to quickly count, obtain the actual quantity of materials, classify and count materials by category, and device Integration of data information with customer MES systems

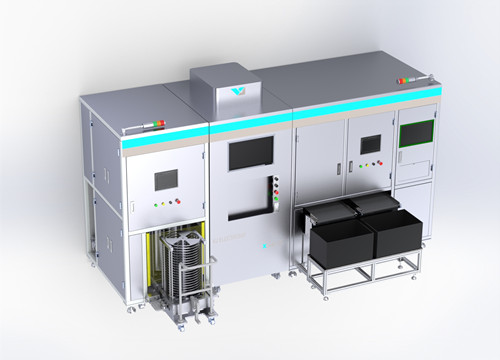

XQuik II Plus is based on the principle of X-ray penetration imaging to obtain image information for non-destructive testing of various product items used in SMT production.

Equipped with a perfect combination of artificial intelligence deep learning software and cloud update system, using software algorithms to quickly count, obtain the actual quantity of materials, classify and count materials by category, and device Integration of data information with customer MES systems

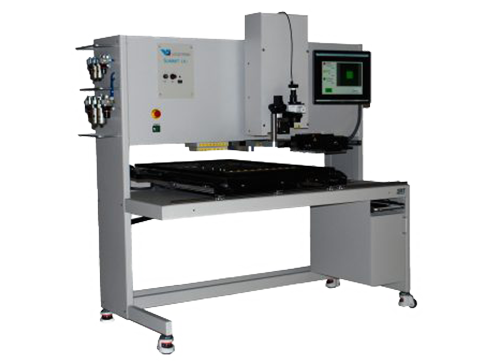

The VJ Electronics Summit 1800i rework system is a high-precision semi-automatic rework system designed for medium-sized SMD components.

The 1800i is equipped with a 1-2-3-GO software operating system, which is simple and intuitive. Effective convective heating provides high heat flux, uniformity, and repeatable rework processes. Automatic non-contact cleaning can safely remove residual solder and eliminate potential damage to solder pads and solder masks.

Proprietary software provides product traceability, configuration file analysis, and configuration file sharing between VJE systems.

A new generation of affordable X-ray testing equipment

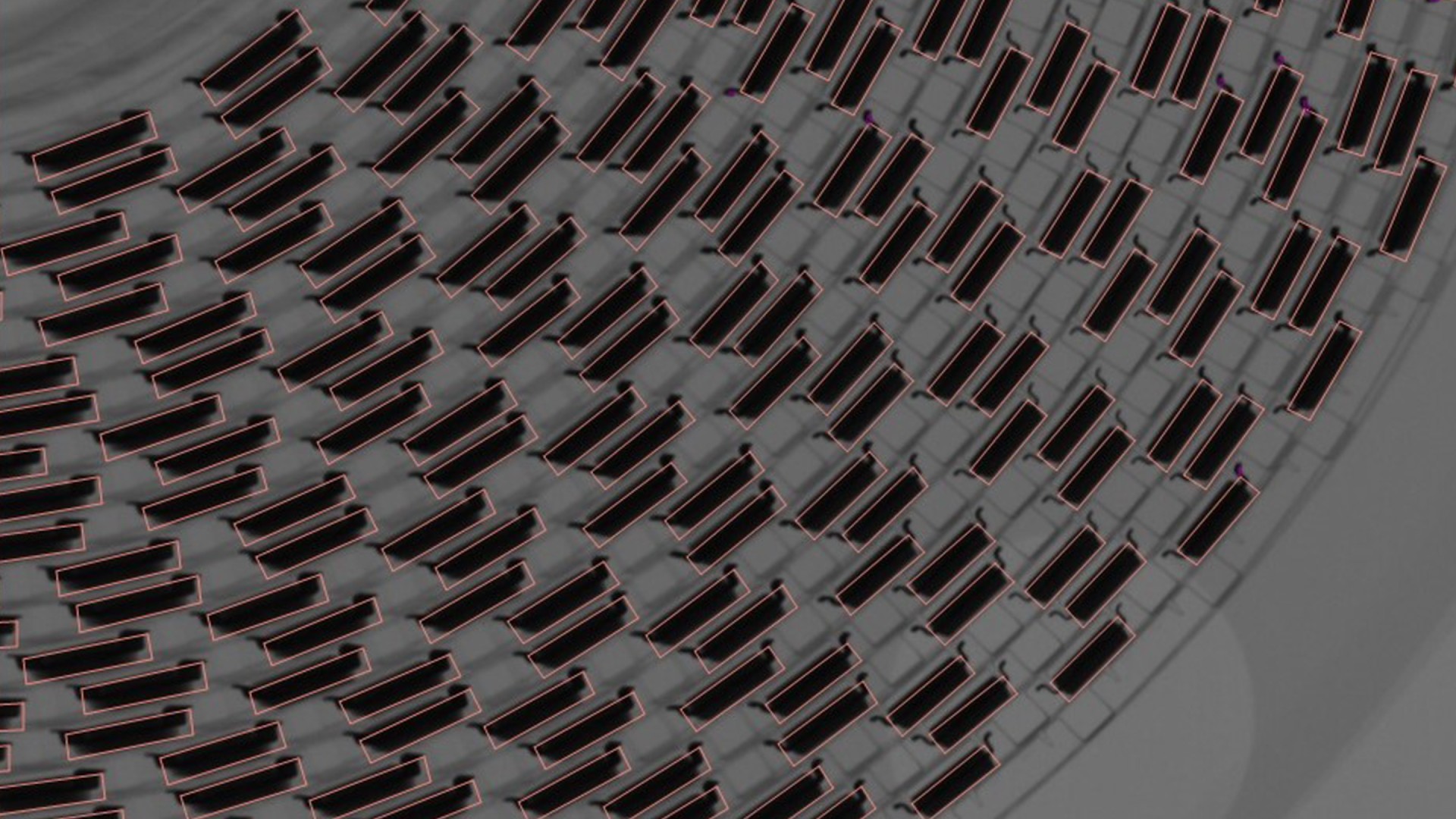

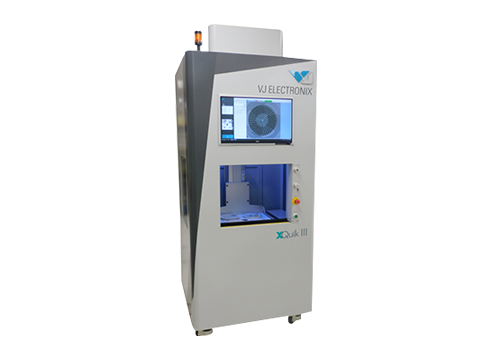

The Xquik III X-ray detection system utilizes innovative technology to achieve precise counting of electronic components

The VJ Electronics XQIII is the fastest component counter on the market with a cycle of less than 10 seconds. The unique imaging technology provides maximum counting accuracy and reliability. The advanced detection algorithm of this system automatically identifies components without the need for cumbersome models, libraries, or cloud connections, making it fast and easy to use.

XQuik's flexible MES interface can be easily configured to communicate with any inventory control system. The built-in barcode reader eliminates additional manual scanning steps and saves time. Automatic detection determines one or a maximum of four small scrolls to be loaded, and tracks the position of the scrolls to eliminate the risk of operator errors.

A rework system for 5G systems and large board applications.

Summit LXi can handle circuit boards up to 25 inches x 47 inches and components as small as 01005.

The rework system uses easy-to-use 1-2-3-GO software, with simple and intuitive operation. Efficient convective heating provides high heat throughput, uniformity, and repeatable rework processes. Automatic non-contact on-site cleaning can safely remove residual solder and eliminate the possibility of damage to solder pads and solder masks. Proprietary software provides product traceability, configuration file analysis, and configuration file sharing between VJE systems.

Minimal operator intervention in the rework system.

Summit2200i can handle circuit boards up to 22 inches x 30 inches and components as small as 01005. The rework system uses easy-to-use 1-2-3-GO software, with simple and intuitive operation. Efficient convective heating provides high heat throughput, uniformity, and repeatable rework processes. The fully electric X, Y, Z, and θ axes allow for fully automatic rework. Automatic non-contact on-site cleaning safely removes residual solder, eliminating the possibility of solder pads and solder masks. Proprietary software provides product traceability, configuration file analysis, and configuration file sharing between VJE systems.

A cost-effective and high-performance solution to address rework needs.

Summit750i can handle circuit boards up to 18 inches x 22 inches and components as small as 0201.

The rework system uses easy-to-use 1-2-3-GO software, with simple and intuitive operation. Efficient convective heating provides high heat throughput, uniformity, and repeatable rework processes. Proprietary software provides product traceability, configuration file analysis, and configuration file sharing between VJE systems.

XQuikII Plus is an improved version of the most installed component counter in the world today. By improving speed, computing accuracy, and reducing costs, XQuikII Plus is your preferred solution.